hallo , i'm triyng to use y3 modules to measure flex on axle and other components , bought some of them in different month and supplier and all of them cannot be trimmed at zero tipically locked at 403 and most important no variation when bf350 flex .

wiring so basic that not possible to make mistakes unless some particular trick , is it possible that all of them have issue if so different suppliers and period ?

instead of using hx711 rthe y3 module would be very useful , anyone have experienced this issue ? or solved ?

Supply 5V/GND to your module and connect your multimeter to gnd/output pin to measure voltage. Adjust potentiometer to get 2V output while sensor is flat. Bend the sensor and observe output voltage.

So if you turn the pot all the way from on end to the other the output is stuck at 403?

exact , several turns of the potentiometer and nothing changed or calibrated or at least 8 or 10 modules from 3 or 4 supplier in different month delivery , i think different arduino uno too .

i think already checked in past the voltage with mltimeter but i try again , no modification with potentiometer and so probably no change in voltage

Which arduino are you using?

Maybe you have the ADC set-up wrong.

Do the whole verification with multimeter like I posted. Also measure the 5V supply voltage.

test done , 4.95v approx supply and zero in any case to the gnd-output pin when connected to arduino , of course unless there must be some read at arduino .

i had a test with same ardunino uno and y3 module using arduino droid and was able to trim at minimum 3 or 4 from the fixed 403 approx on pc ide but then any variation visible when bend sensor bf350 .

lot of board , lot of modules , how can they be all defective ?

using an hx711 amplifier and a small double straing gauge i can read amazing sensitive but no way to use y3 module that could be very simple ( and lot bought for this pourpouse )

is there some capacitor to add to increase funtion as i remember to read somewere ? or at least let them work ![]()

tried with a0 and then a1 to be sure , no change .

not familiar with adc setting if this could be the problem .

Not sure I follow what you mean there.

Connections should be like this:

VCC->5V

GND->GND

OUT-> A0

Please post your code, so we can see if something is wrong.

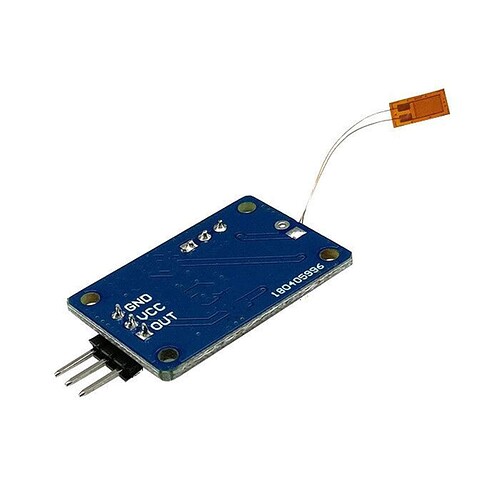

here is the pin connection , very easy with gnd and supply 5 v and signal pin to a0

power supply seem to work as i can measure 4.95 volts but no variation to module output nor trimmin nor bending bf350 sensor , only with arduinodroid it's possible to trim .

if nothing wrong with connection or arduino uno general setting the only left possibility is all board not working but is it strange with so different brands and suppliers

code below :

#define SENSOR_PIN 0

void setup()

{

Serial.begin(9600);

}

/* Main loop */

void loop()

{

Serial.print("Sensor: ");

Serial.println(analogRead(SENSOR_PIN));

/* Wait 1 second and then read again */

delay(1000);

}

try A0 also try anothe pin like A4

only with arduinodroid it's possible to trim .

Does the strain gauge work in this case?

with arduino droid the pin A0 is responsive with trimming , i'm able to reduce from some hundreds value to around zero ( 2 or 3 ) but NO change in serial print value when i bend bf350 sensor .

on arduino ide from pc dosen't work trimming and sensor too . ( really strange )

doing the test with multimeter on the board between gnd and out data pin is it correct to say that i must read change in volts especially if greatly bended ?

if not i have to assume that the module itself doesnt work , correct ?

changing from " PIN 0 " to PIN A0 " doesnt' work trim nor change data sensor

just changed to amiga board and brand new y3 module out of box ( no shortcut connecting ) and same no trimming no variation both with A0 or 0 in the code , this try give a fixed 1024 value , not possible to trim or read change when flex

Do what I suggested on post#2. If that doesn't output voltage change on your multimeter when bending, you are wasting your time with Arduinos.

Maybe your strain gauge is not bf350?

You can measure resistance of your (disconnected) strain gauge with multimeter, it should be ~350ohm while flat.

Hard to believe but it does seem that way

Have you got the strain gauge correctly mounted on to an item whose strain you are trying to measure?

Strain gauge bonding procedure

Strain gauge installation applications

or are you simply bending the unmounted strain gauge?

test done quite immediately , maybe i badly communicate in post 7

applied 5 volt supply to y3 module and measure gnd to out so i was able to measure volts once trimming , result 3,5 fixed and no way to modife even lightly ot trim .

i'm simply bending bf350 , in one of this module disconnected and measure correctly around 350 resistance .( solded a new bf350 too )

simply bending another circuit hx711 with another double embedded resistors work even with a paper sheet , impressive sensing .

i have to simply say all modules failed but beneath the too easy conclusion it's often masked a better and real solution ( usually )

at least 10 y3 module it's no statistic a malfunction .

Then it's not working.

Strange if you have 10 non-working ones...

that's my thought , it 's not statistic to have so much modules from 3 or 4 suppliers in 6 month period all not working tried with different arduino type with 2 different code .

is there a same story of cheap modules all doesn't work in previous times ?

if not the question i still have , were is the mistake ?

You can trace out the connections on the module and draw a schematic. Then you can see if the modules are designed right.

this means to do the designer work that i think already bought for done ,could be interesting and challenging but complicated for my electronic skills .

they are widespread , how they can all be badly designed ?