I am building a wheeled robot platform using a custom PCB, 4x A4988 and 4x NEMA 17 stepper motors. I am using steppers purely for precise speed and position control.

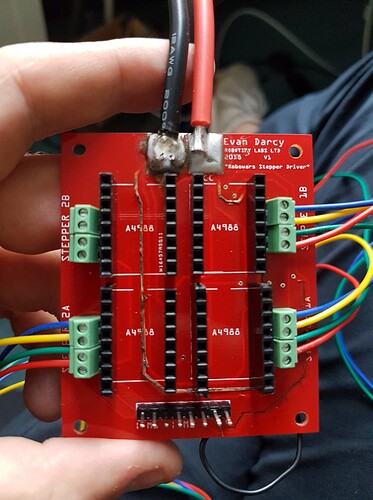

I recently had a PCB made, I was doing some testing today. I was able to successfully run one stepper motor from it. The power supply is a 16v lion battery pack. When I tried to run two, it ran briefly before I see a puff of smoke and notice that a PCB trace appears to have burnt up and come loose from the board. You can see the brown trace on the photo of my PCB I posted. It was the GND trace which is connected to each A4988, the power supply and an Arduino Nano.

I attempted to repair this fried trace by soldering an external jumper cable, when I ran circuit again, I was struggling to get the stepper to run consistently from the driver. I began troubleshooting with a voltmeter and another poof of smoke!

I have fried all four of my drivers as well as two Arduino Nanos. Feeling rather frustrated as I can seem to figure out exactly what's going wrong.

I have a feeling that I need to put a resistor between the GND of the main power supply and the Arduino GND, that's the best I could come up with for the fried Arduino.

As for the PCB traces exploding...I think the maybe there is too much current going through a PCB trace of that width?

I'm attaching a photo of my PCB. All help is appreciated. I'm a bit lost at this point.

If any more info is required let me know (diagrams etc).

Here is a link to my steppers (17HS4401)

Here is the code I was using. Bear in mind I have two A4988 drivers connected to same GPIO pins for each side of the robot

// defines pins numbers

const int stepPin = 6;

const int dirPin = 7;

void setup() {

// Sets the two pins as Outputs

pinMode(stepPin,OUTPUT);

pinMode(dirPin,OUTPUT);

}

void loop() {

digitalWrite(dirPin,HIGH); // Enables the motor to move in a particular direction

// Makes 200 pulses for making one full cycle rotation

for(int x = 0; x < 200; x++) {

digitalWrite(stepPin,HIGH);

delayMicroseconds(50);

digitalWrite(stepPin,LOW);

delayMicroseconds(50);

}

delay(1000); // One second delay

digitalWrite(dirPin,LOW); //Changes the rotations direction

// Makes 400 pulses for making two full cycle rotation

for(int x = 0; x < 400; x++) {

digitalWrite(stepPin,HIGH);

delayMicroseconds(50);

digitalWrite(stepPin,LOW);

delayMicroseconds(50);

}

delay(1000);

}