Hi!

I’m currently in the process of building a pottery wheel for a university project.

First of all: I’m not experienced in electronics, I study product design and am able to get help building & connecting all the electric stuff.

Its not really a robot, but I think controlling the wheel with an Arduino could help, and might make it more future proof & expand possibilites.

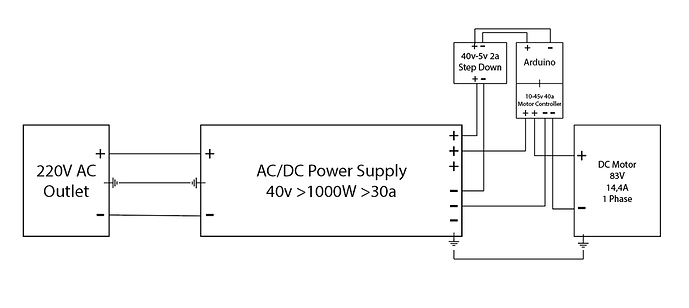

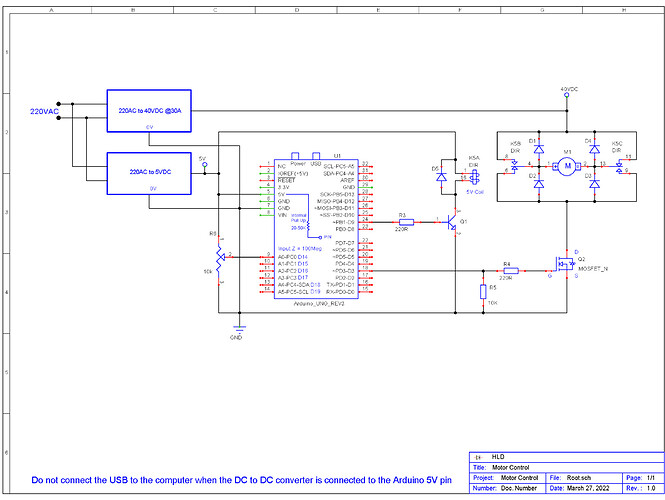

I have an old brushed DC motor, 83v, 1kw, geared to 592rpm.

Planning to run it at around 40v (depening on what kind of power supply I can find) to get the RPM down to a usable level.

Pottery wheels usually have a maximum rpm between 250-325.

Now to controlling the RPM & direction:

I need to controll the rpm with a foot pedal, not spring loaded - a volume pedal for an electric guitar would be perfect.

The directions also need to be reversible.

Thats where the Arduino idea comes in.

Does that make sense for you until now, or am I already on a bad path?

Secondly i’d also need to know what hardware I would need for all this.

I would obviously need an Arduino, I suspect a pretty basic one would be enough (as I dont need a lot of sensors etc.)

Then I’d need a DC controller that I can hook up after the PSU and before the motor - correct?

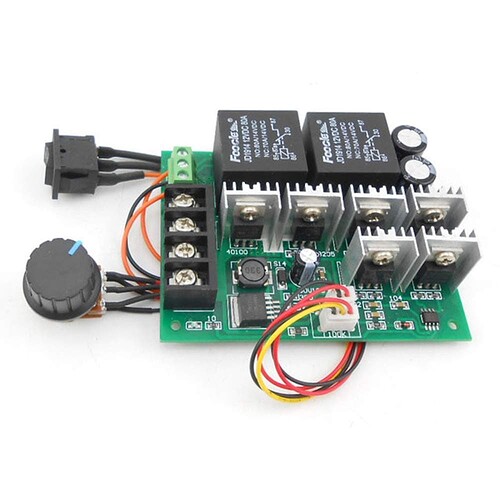

Would this one work: Cytron Single 10- 45V, 40A Brushed DC Motor Controller - RobotShop ?

We’ve had a week of programming the Arduino, and we have somebody that can help with the software side of things.

Im open to any suggetions and ideas, I dont have to use an Arduino - I just havent found another good way to use foot controlls.

Thank you!

Felix