Hi everyone, this is my first post, so I will try to be as detailed as possible. If you need more information, please ask, and I will do my best to respond ASAP.

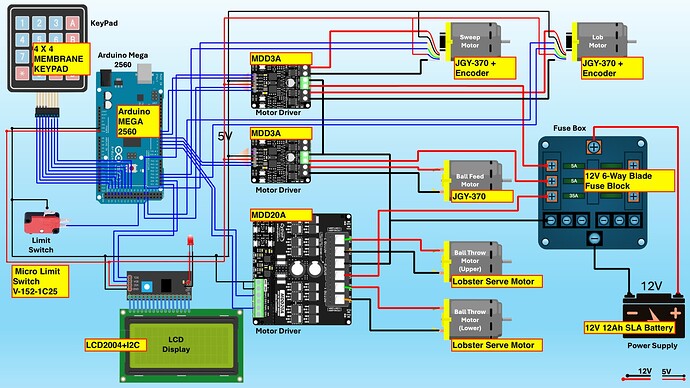

Here is my situation: I have a tennis ball machine that I built using an Arduino Mega and a bunch of other components, as shown in the picture. Please note that the picture is slightly incorrect. The fuse box has two 2A fuses and one 35A fuse, unlike the picture, which shows 5A, 2A and 35A fuses.

I use two Cytron MDD3A motor drivers to drive three 12V gear motors with a stall current of 1A each. I also use an MDD20A to drive two 12V motors that can do 6000 RPM and draw a larger current. Unfortunately, I don't have specs on that motor, but when I tested it with a 20A fuse going into the driver, it blew the fuse. It works fine with a 35A fuse. That is 35A total current going to the driver, and the driver can handle 20A per channel, so I am under the maximum continuous current the driver can handle.

Now, like an idiot, I connected the battery to the fuse box in reverse. Rookie mistake, but stuff happens, right? I immediately noticed smoke coming from the fuse box and disconnected the battery as quickly as I could to prevent any damage (instinct, I guess).

Upon checking, I noticed the 35A fuse was blown. The two 2A fuses were still intact. But when I replaced the 35A fuse, the circuit was not working correctly. The MDD20A was sending power to the motors as soon as I connected the power, which is not how it usually behaves. It only sends power to the motors if I press one of the onboard buttons or if the Arduino sends the signal.

I also noticed that the two MDD3As were not sending any power to the worm gear motors when I tested them using the onboard buttons. In case you are wondering what I am referring to when I say "onboard buttons," these are forward and reverse buttons on the motor driver that Cytron provides for quick testing. Press them, and the driver sends power to the motor without any signal from the Arduino.

Okay, I need to ask the question at some point, so here it goes. I am still debugging the circuit and may have other questions that I may post, but for now, my question is: why did my MDD3A drivers get fried even with reverse polarity protection? The larger MDD20A works fine, but the smaller MDD3As seem to have given up the ghost. I should add that when I tested the voltage at the output of the MDD3A, it shows 5V when no load is connected, but when a load is connected, it goes down to 0.xx V, which is practically 0.

Luckily, I used the 5V output from the MDD3A to drive my Arduino Mega, and that seems to have survived the mishap, as did all the other motors and input components. Basically, the MDD3As seem to have sacrificed themselves to protect the other components they provide power to.

This has turned out to be more of a story than a pointed question, and I apologize for that. I am not an electronics expert and rely on a lot of information on the internet to get by. Thanks for your valuable input.