Recently I built a 4-axis robot for palletization applications with its 4th axis being mechanically controlled, the rest of the 3 axis are controlled by nema17 motors using a drv8825 driver, a cnc shield v3 and a arduino mega, the problem I am encountering is that despite de correct calculations of the inverse kinematics, I am struggling with the precision of its movements, mainly translating on its y-axis and z-axis, I attached below some images, videos and the code

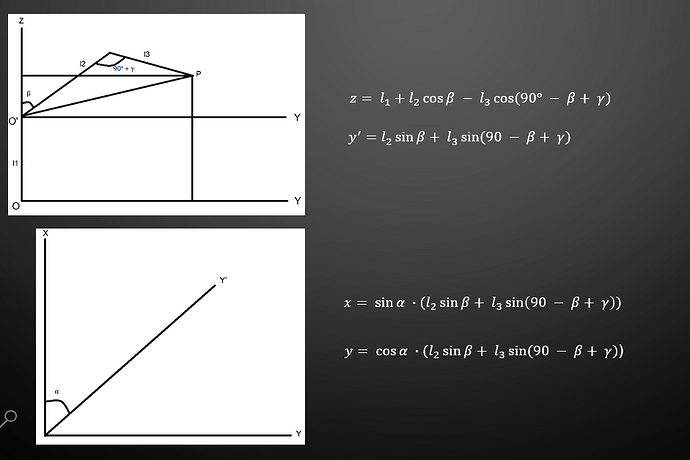

Forward Kinematics

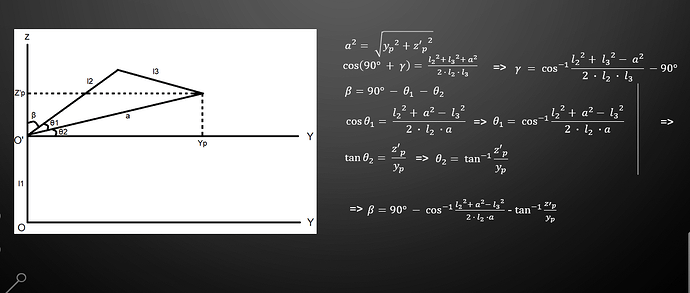

Inverse Kinematics

#include <MobaTools.h>

#include <math.h>

#include <FastTrig.h>

#include <string.h>

#define pin 38

#define step1 2

#define step2 3

#define step3 4

#define dir1 5

#define dir2 6

#define dir3 7

#define l1 69.5

#define l2 100

#define l3 100

MoToStepper motor1(800, STEPDIR);

MoToStepper motor2(800, STEPDIR);

MoToStepper motor3(800, STEPDIR);

MoToServo servo1;

int step = 0, pos1 = 0, pos2 = 0, pos3 = 0, servo_pos = 0;

double xp, yp, zp, alpha1, beta1, gamma1;

bool Joint_Mode = true, First_Message = true, Repeat = false, Play = false;

double degreesToRadians(double degrees) {

return degrees * M_PI / 180.0;

}

double radiansToDegrees(double radians) {

return radians * 180.0 / M_PI;

}

void setup() {

Serial.begin(9600);

delay(1000);

servo1.attach(pin);

motor1.attach(step1, dir1);

motor2.attach(step2, dir2);

motor3.attach(step3, dir3);

motor1.setMaxSpeed(200);

motor2.setMaxSpeed(200);

motor3.setMaxSpeed(200);

motor1.setRampLen(10);

motor2.setRampLen(10);

motor3.setRampLen(10);

Serial.println("Set the Step size using - and + keys.");

Serial.println("Joint mode can be toggled on and off with the q ans w keys.");

Serial.println("Effector is controlled using i, o and p keys");

Serial.println("The robot is controlled with the numpad using all the numbers");

alpha1 = motor1.currentPosition() * 0.1125;

beta1 = motor2.currentPosition() * 0.1125;

gamma1 = motor3.currentPosition() * 0.1125;

xp = (l1 * sin(degreesToRadians(beta1)) + l3 * sin(degreesToRadians(90 - beta1 + gamma1))) * sin(degreesToRadians(alpha1));

yp = (l1 * sin(degreesToRadians(beta1)) + l3 * sin(degreesToRadians(90 - beta1 + gamma1))) * cos(degreesToRadians(alpha1));

zp = l1 + l2 * cos(degreesToRadians(beta1)) - l3 * cos(degreesToRadians(90 - beta1 + gamma1));

zp = zp - l1;

}

void loop() {

double alpha, beta, gamma;

if (Serial.available() > 0) {

char input = Serial.read();

switch (input) {

case '+':

if (step >= 100) {

Serial.println("Step can't be set higher than 100!");

break;

}

Serial.print("Step set to: ");

if (step < 5)

++step;

else if (step == 5)

step += 5;

else

step += 10;

Serial.print(step);

Serial.print('\n');

break;

case '-':

if (step <= 0) {

Serial.println("Step can't be set as a negative value!");

break;

}

Serial.print("Step set to: ");

if (step <= 5)

--step;

else if (step == 10)

step -= 5;

else

step -= 10;

Serial.print(step);

Serial.print('\n');

break;

case '7':

pos1 += step;

xp += step;

break;

case '8':

pos1 = 0;

xp = 0;

break;

case '9':

pos1 -= step;

xp -= step;

break;

case '4':

pos2 += step;

yp += step;

break;

case '5':

pos2 = 0;

yp = 100;

break;

case '6':

pos2 -= step;

yp -= step;

break;

case '1':

pos3 += step;

zp += step;

break;

case '2':

pos3 = 0;

zp = 100;

break;

case '3':

pos3 -= step;

zp -= step;

break;

case '0':

pos1 = 0;

xp = 0;

pos2 = 0;

yp = 100;

pos3 = 0;

zp = 100;

break;

case 'i':

if (servo_pos == 180) {

Serial.println("Servo cant go above 180");

break;

}

servo_pos += 10;

break;

case 'o':

servo_pos = 0;

break;

case 'p':

if (servo_pos == 0) {

Serial.println("Servo cant go below 0");

break;

}

servo_pos -= 10;

break;

case 'q':

Joint_Mode = true;

Serial.println("Joint mode on");

break;

case 'w':

Joint_Mode = false;

Serial.println("Joint mode off");

break;

}

if (Joint_Mode == false) {

alpha = xp;

double l = sqrt((xp * xp) + (yp * yp));

double a = sqrt((zp * zp) + (l * l));

beta = degreesToRadians(90) - acos(((l2 * l2) + (a * a) - (l3 * l3)) / (2.0 * l2 * a)) - atan(zp / l);

gamma = acos(((l2 * l2) + (l3 * l3) - (a * a)) / (2.0 * l2 * l3)) - degreesToRadians(90);

//alpha = radiansToDegrees(alpha);

gamma = radiansToDegrees(gamma);

beta = radiansToDegrees(beta);

motor1.moveTo(alpha / 0.1125);

motor2.moveTo(beta / 0.1125);

motor3.moveTo(gamma / 0.1125);

Serial.print("alpha = ");

Serial.println(alpha , 10);

Serial.print("beta = ");

Serial.println(beta , 10);

Serial.print("gamma = ");

Serial.println(gamma , 10);

Serial.println();

} else {

motor1.moveTo(pos1 * 16);

motor2.moveTo(pos2 * 16);

motor3.moveTo(pos3 * 16);

}

servo1.write(servo_pos);

}

}

I modified some bits of the code, taking into account the x and y axis not the z and y, but the problem still persists, the robot translates at a 45 degree angle on the z axis, I tried all the combinations with adding, substracting 45 and 90 degree angles, I dont know what to do, any suggestions?