Hello everyone,

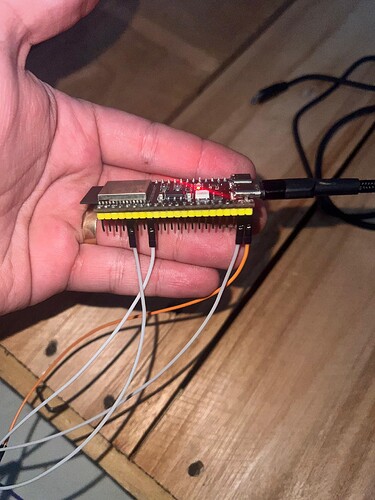

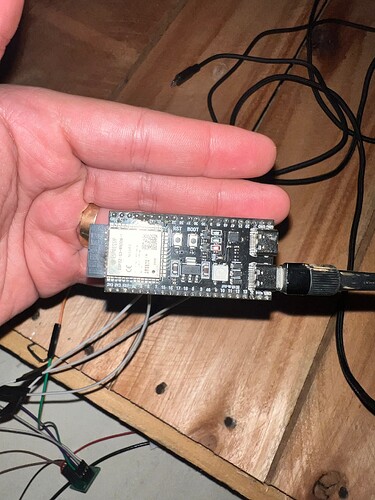

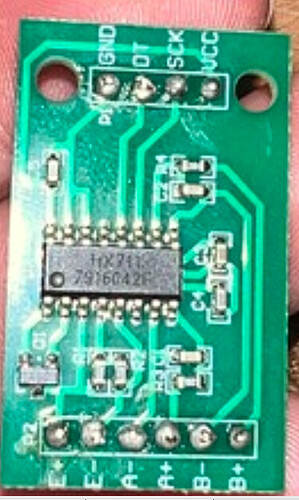

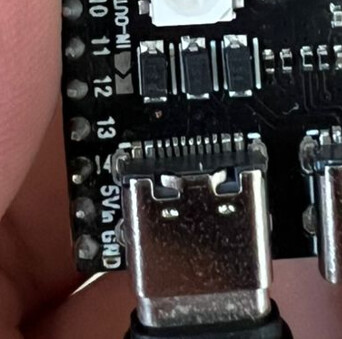

I’m trying to build a digital scale that will upload data to a database so I can monitor the stock levels of a specific part over time. I’m using four 50kg load cells, an HX711, and an ESP32-S3 DevKitC-1.

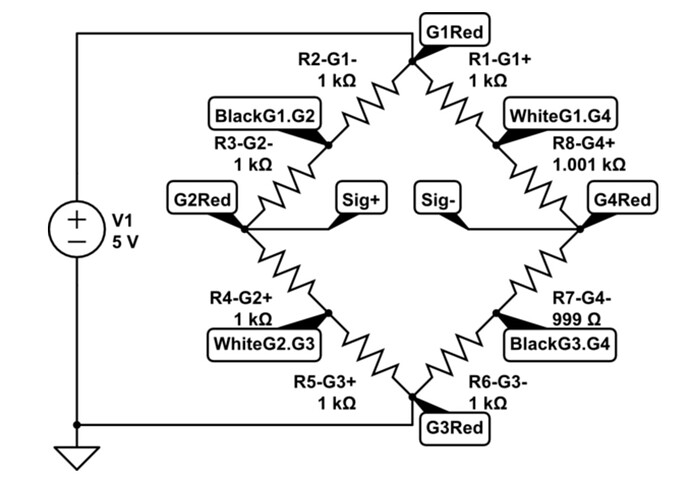

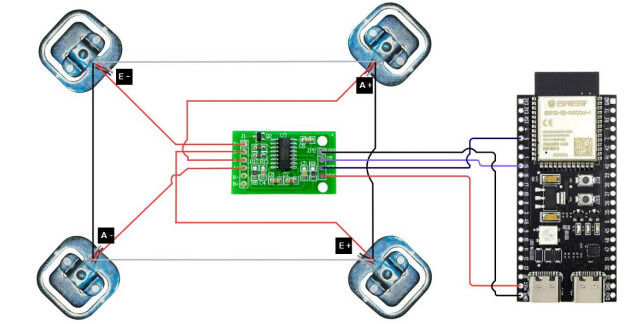

I assembled everything following the diagram below, where you can see both the theory and an actual photo of the setup, including all the connections.

However, the readings are very strange. I ran some tests I found in other posts, and one of them was to measure the resistance between the wires of the load cells. Here are the results, using a multimeter set to 20k ohms:

Top left ![]()

20k - 1.97 (black-white)

20k - 0.98 (black-red)

20k - 0.98 (red-white)

Bottom left ![]()

20k - 1.97 (black-white)

20k - 0.98 (black-red)

20k - 0.98 (red-white)

Bottom right ![]()

20k - 1.97 (black-white)

20k - 0.98 (black-red)

20k - 0.98 (red-white)

Top right ![]()

20k - 1.97 (black-white)

20k - 0.98 (black-red)

20k - 0.98 (red-white)

From what I understood in another post, the red wire should be the one connected to E+ E- A+ A-.

I’ve redone all the connections between the load cells, and also between the HX711 and the ESP32, but I still can’t figure out what’s going on. I’ll also share the code I’m using. I’m begging for any help to get this project working.

Top Right is the A+, Botom Right E+, Botom Left A-, Top Left E-

I've tried to power the sistem with a apple charger and the usb port from my laptop.

It is my first project, plz hope u understand.

If you need any additional information, photos, or anything else, just let me know and I’ll be glad to share it right away.

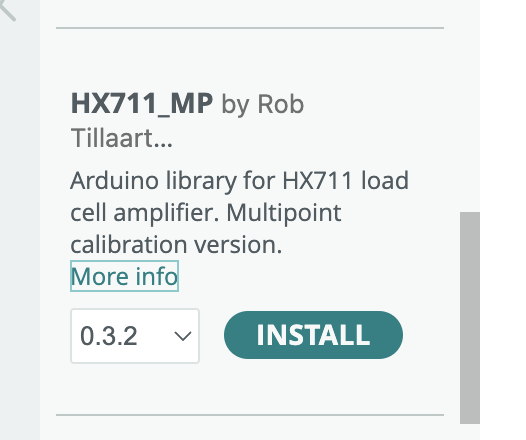

Code: #include <HX711_ADC.h>

#include <WiFi.h>

#include <WebServer.h>

// Pinos HX711

const int DOUT_PIN = 5;

const int SCK_PIN = 15;

HX711_ADC scale(DOUT_PIN, SCK_PIN);

// Wi-Fi

const char* ssid = "MYWIFINAME";

const char* password = "MYWIFIPASS";

// Fator de calibração (ajuste depois)

const float calibrationFactor = 1.0;

WebServer server(80);

float currentWeight = 0;

// HTML que será servido em "/"

const char indexPage[] PROGMEM = R"rawliteral(

<!DOCTYPE html>

<html>

<head>

<meta charset="utf-8">

<title>Balança em Tempo Real</title>

<style>

body { font-family: sans-serif; text-align: center; margin-top: 50px; }

#weight { font-size: 4em; color: #007bff; }

</style>

</head>

<body>

<h1>Leitura da Balança</h1>

<div id="weight">--.- g</div>

<script>

async function updateWeight() {

try {

const resp = await fetch('/reading');

const data = await resp.json();

document.getElementById('weight').textContent = data.weight.toFixed(2) + ' g';

} catch (e) {

document.getElementById('weight').textContent = 'Erro';

}

}

// Atualiza a cada 200 ms

setInterval(updateWeight, 200);

// Primeiro fetch imediato

updateWeight();

</script>

</body>

</html>

)rawliteral";

void handleRoot() {

server.send_P(200, "text/html", indexPage);

}

void handleReading() {

// Retorna JSON com peso atual

String json = String("{\"weight\":") + String(currentWeight, 2) + "}";

server.send(200, "application/json", json);

}

void setup() {

Serial.begin(115200);

// Inicia e tara a balança

scale.begin();

Serial.println("Tareando sensor...");

delay(2000);

scale.start(2000, true);

Serial.println("Tare feita!");

// Conecta Wi-Fi

Serial.print("Conectando a ");

Serial.print(ssid);

WiFi.begin(ssid, password);

while (WiFi.status() != WL_CONNECTED) {

delay(500);

Serial.print(".");

}

Serial.printf("\nConectado! IP: %s\n", WiFi.localIP().toString().c_str());

// Rotas

server.on("/", HTTP_GET, handleRoot);

server.on("/reading", HTTP_GET, handleReading);

server.begin();

}

void loop() {

// Atualiza o sensor

scale.update();

// Obtém leitura bruta e aplica fator de calibração

currentWeight = scale.getData() / calibrationFactor;

// Atende clientes web

server.handleClient();

}