I was hoping other consumer grade printer users would come in with their opinions and experiences.

Keep in mind the following are just my opinions. My experience comes from using $100K+ Stratasys printers, overpriced MakerBot printers at work and my personal 7 year old Original Prusa i3 MK1. My personal hardware and software has not been upgraded in 7 years so I'm not up to date on todays offerings.

As for the printer you posted, it doesn't have a heated build plate. This means you can only print with PLA and TPU. You will most likely be forced to print a raft as a base for it to level and adhere to the plate. My opinion is PLA is brittle, used mainly for modeling figurines. You can use it for mounts, standoffs and housings as long as you are not putting too much load on it. I have not used PLA in years. TPU is great for hinges, gaskets, spacers, phone cases etc. I use TPU when the job calls for it.

The printer you posted gets mixed reviews, mostly good. If it meets your needs, go for it.

As for the Ender I suggested, I have never used nor seen an Ender before. I have seen parts printed from them and they were comparable to my Prusa. Enders are considered the gold standard for < $300 printers. Prusa is considered the gold standard for $1000 range printers.

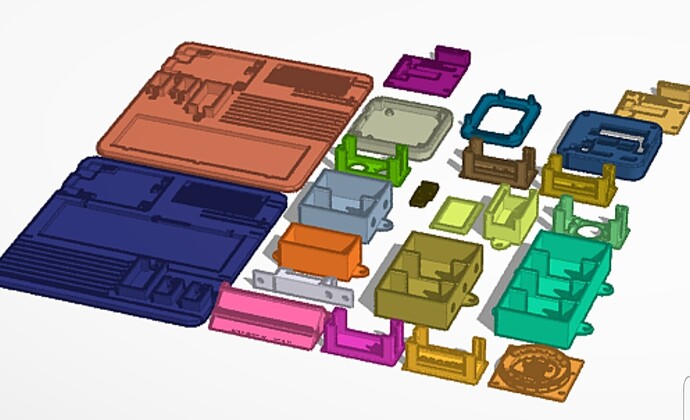

You also have to consider the other half of the task. Designing your part and creating a gcode print file. There are several free CAD software tools available for this. TinkerCad or SketchUp may be all you will need for basic geometric shapes. Fusion 360 or SolidWorks would be a step up but become more complicated. I started off using AutoCAD too many years ago, then went to Pro E, which became CREO probably 12 years ago. CREO is all I know so I have stayed with that. I Do Not recommend a beginner to start on CREO. I'm sure there are much easier tools out there.

CAD Google Search

The CAD software generates either a .STL or .OBJ file. With that, you need 3D slicer software such as Cura or Slic3r to generate the actual gcode the printer uses to print your part. Easythreed has this comment on Amazon:

"For beginners, if you don't know how to use 3D slicing software, you can directly download the model file (Gcode file) to the TF card, insert it into the printer, and start printing."

I have no idea what they are trying to say here. You need to use the 3D slicing software to create the gcode. There may be web sites that offer gcode. Web sites such as Thingiverse offer STL files and you run that through your slicer to create the gcode.

I say all this so you don't think you can buy a printer and immediately start printing your own custom designed parts. This requires the extra effort of designing the part and creating the proper print files with additional software. You might want to start by downloading various CAD software to see if you can create parts with it before you purchase the printer. The purchase is the easy part.

I hope this helps